How It Works

Streamlined, Cutting-edge Design

At the heart of Firefly is an advanced, aeroderivative turbogenerator.

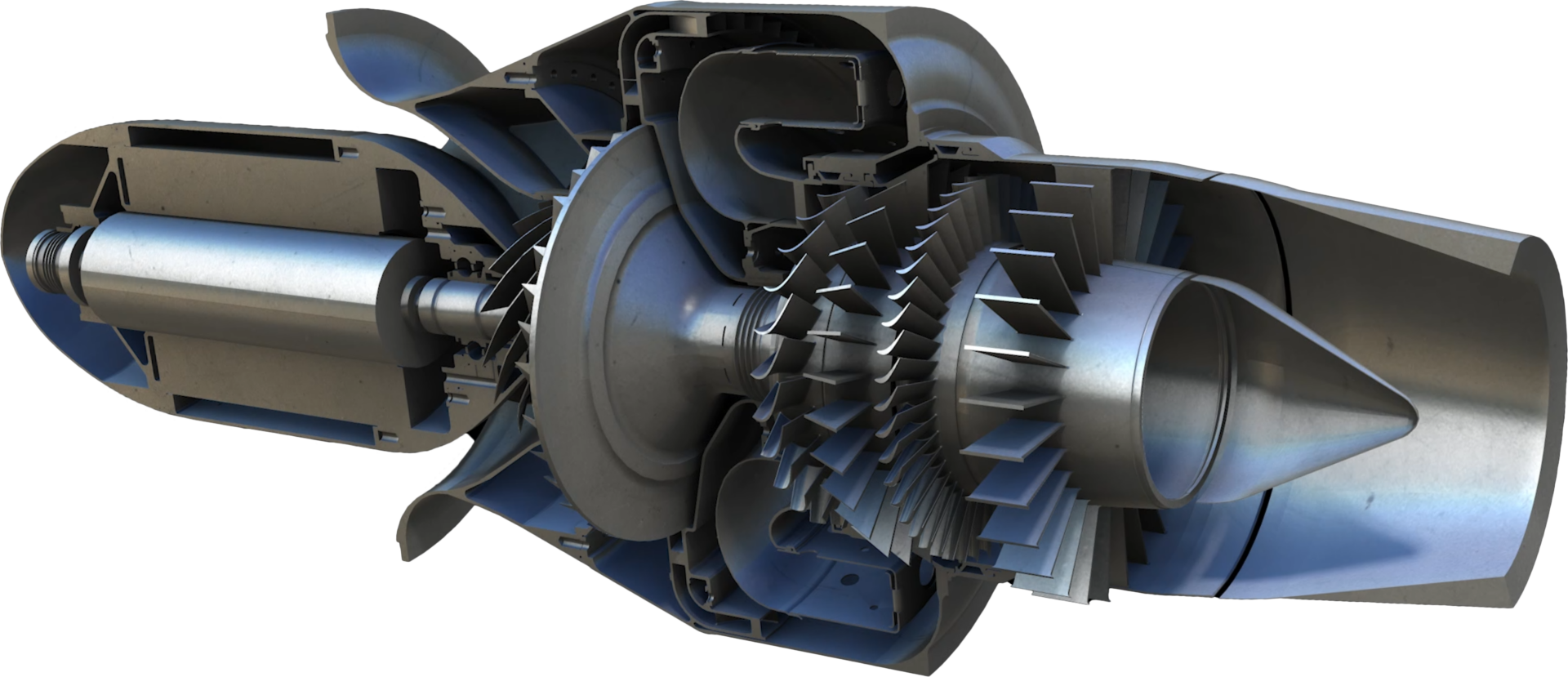

The Firefly Power System leverages an innovative turbogenerator which produces 1.5 MW using a variety of liquid fuels including diesel #2, biodiesel, JetA, JetB, JP4 and JP8. With a straightforward changeout of its injectors, Firefly can switch to gaseous fuels such as hydrogen-based CH4. The system’s fuel flexibility and compact, yet powerful design make Firefly an ideal solution for operations where sustainability and mobility are key.

Powering a new path

Firefly is a 1.5 MW mobile and power-dense system with digital inverter-based output power. It was developed through a blending of technologies, innovation and industrial convergence.

The integrated permanent magnet motor is small, light, quiet and highly efficient. It doesn’t require external power sources for magnetization, which helps reduce energy loss.

A patented, direct-drive turbogenerator creates mechanical energy through a fuel burning turbine, then converts the energy into electrical power through an integrated permanent-magnet motor. This design eliminates the need for a gearbox or accessory starter.

Digital power electronics convert the turbogenerator’s electrical power output into usable grid-quality power, and includes a high voltage battery for black-start capability.

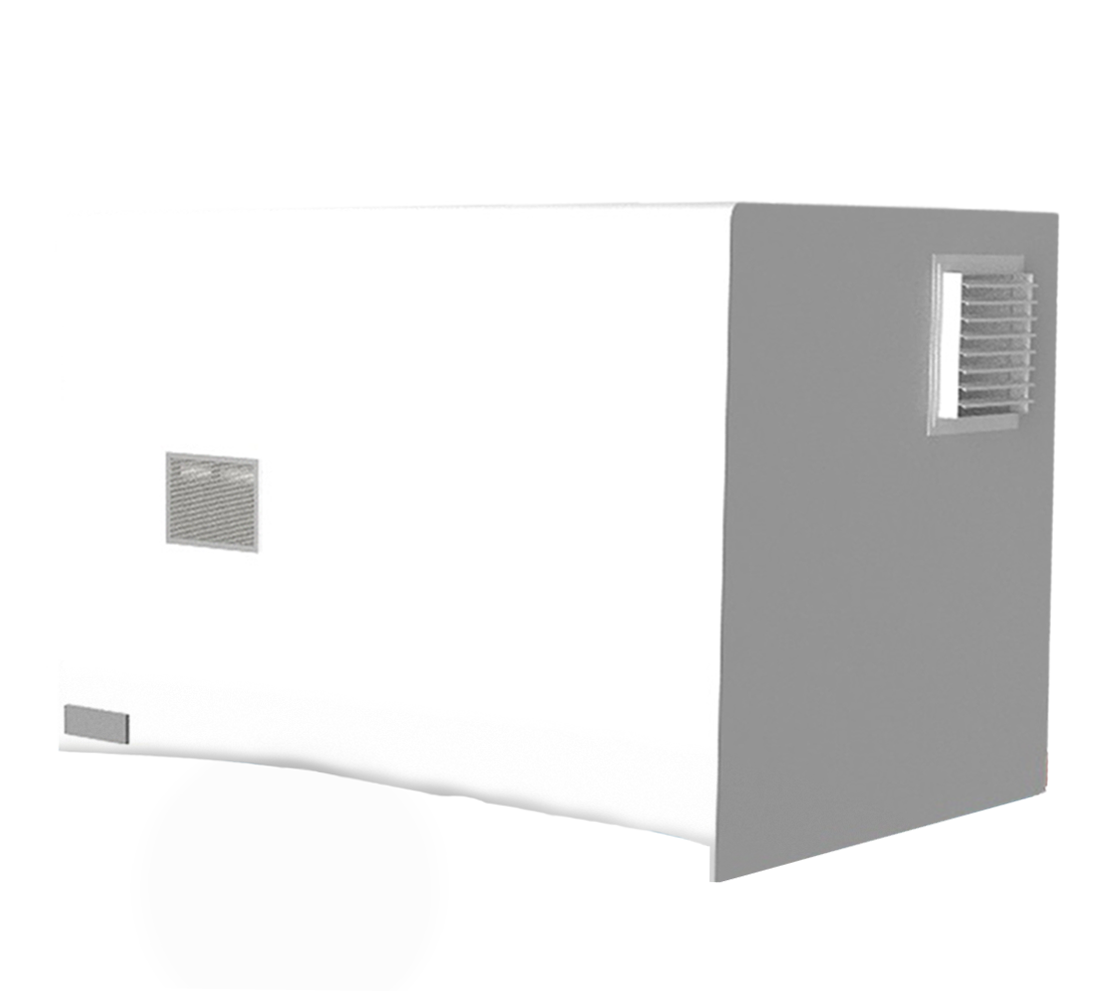

An easily accessible enclosure encases and protects all components, reduces acoustic signature, and facilitates transportability.

A reliable control module provides the system’s user interface, while controlling and monitoring all sub-systems for complete integration and protection.

Rigorous Testing Confirms the Firefly Difference